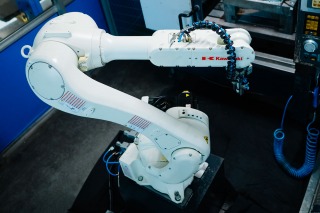

Ad Hoc Machining and Treatments of Every Single Piece

Sabrest is capable of planning and managing all types of machining processes, from the most simple and standardised up to the most complex and customised in terms of slitting, modelling and finishing for each single request from the clients and for any specific sector, Sabrest ensures the optimization of costs and full respect of the agreed lead time. Every stage is automated and supervised by qualified and expert operators, who inspect the quality of the piece even in high volume manufacturing. Sabrest also offers a wide selection of machining and finishing, such as various types of heat or galvanisation treatments, painting, micro sandblasting, brightening and polishing, Tenifer treatment, quenching, Nitemper amongst many others.

- Galvanic Treatments

- Phosphating

- Galvanising various colours

- Nickel Plating

- Burnishing

- Dacromet

- Geomat

- Niploy

- Chromium Plating

- Surface Treatments

- Painting

- Tumble finishing

- Sandblasting

- Micro-sandblasting

- Brightening

- Polishing

- Heat Treatments

- Quenching

- Nitriding

- Induction hardening

- Nitemper

- Case Hardening

- QPQ

- Carbonitriding

- Tenifer